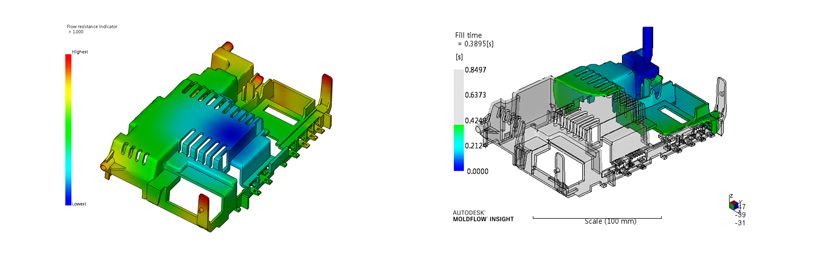

DFM & Mold Design

We provide engineering guidance to help you design moldable parts that are optimized for manufacture. From tool design concepts to process development and validation, we ensure that all aspects of production meet the ultimate goal of producing high-quality injection molded parts.

Product Design Assistance

Support in the design of product features, specs and industrial design follow. We can

support you in development of your new projects or re-design current products and

implement these steps on behalf of clients by meeting in person and teleconferencing with

you and your sales & marketing and technical people each step of the way.

Product Development

- Early Stage Engineering Support

- Quality Requirement Planning

- Material Selection Consultation

- Mold Concept Planning

- Part Optimizing

- Design For Manufacturing

- Cycle Time Optimization

Mold Design Support

- Mold drawing 2D

- Mold drawing 3D

- Design for Manufacturable

- Mold Design Checked

- Mold Design Specification

- Mold Design Optimized

- Cooling Design Optimization

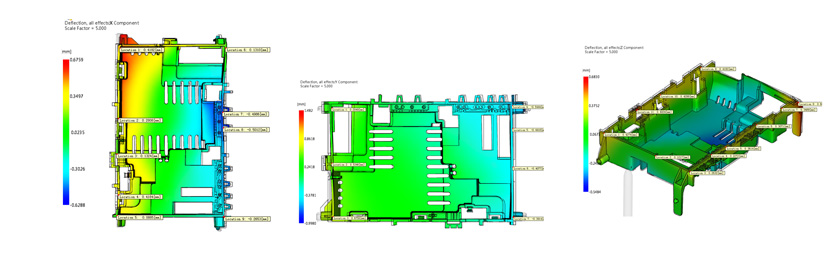

Engineering Software

- Auto CAD

- Unigraphics NX

- Autodesk Moldflow

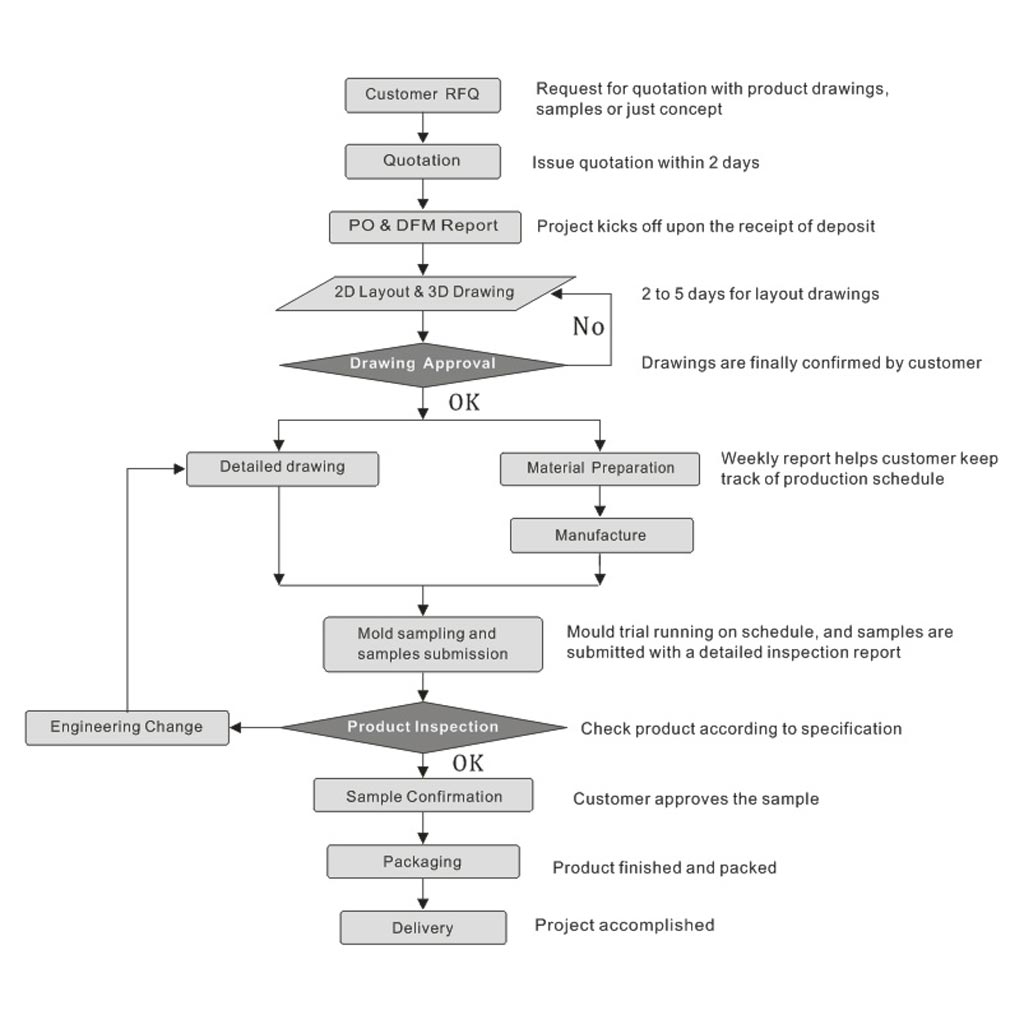

Project Management

We have six (6) professional English-speaking project management engineers to follow tooling design, tooling making and testing to provide services as below for you:

- Early Stage Engineering Support

- Quality Requirement Planning

- Material Selection Consultation

- Mold Concept Planning

- Design for manufacturability Services

- Mold flow analysis Services

- Product Testing Services

- Material Testing and Validation Services

- Product Development Services

- Product Design Assistance

- Professional Engineering Services

- Projects Schedule Planning

- Tooling Weekly Process Report

- Mold Trailing

- Mold & molding validation report

- Exception handing in logistics

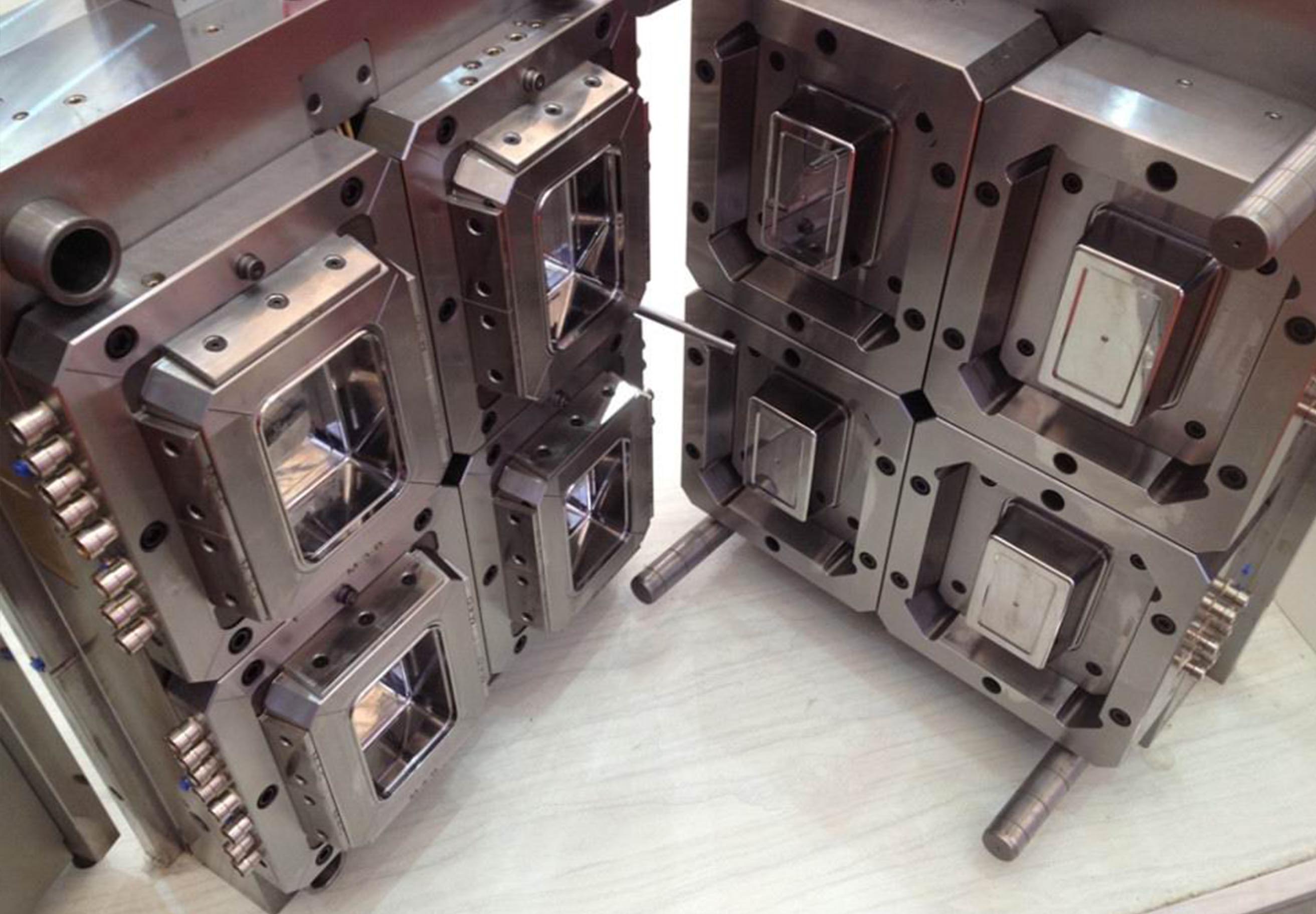

Mold Manufacturing

Our mold making department is capable of constructing numerous types of injection molds with significant experience in most modern mold construction systems.

- High cavitation molds

- Appropriate hot runner design and selection.

- Low cycle molds (5000 shots)

- High cycle molds (over 10 million)

- Multi-Material molding (2k) and insert molding

- Gas Assist molding

- Foam Injection techniques

- Close tolerance Molding

- Elastomeric molding

- Compression molding

- In-Mold Labeling

- Thin wall molding

- High Heat molding

- Precise part moldings

Assembly Room

Bridge Type CNC

CNC Machine

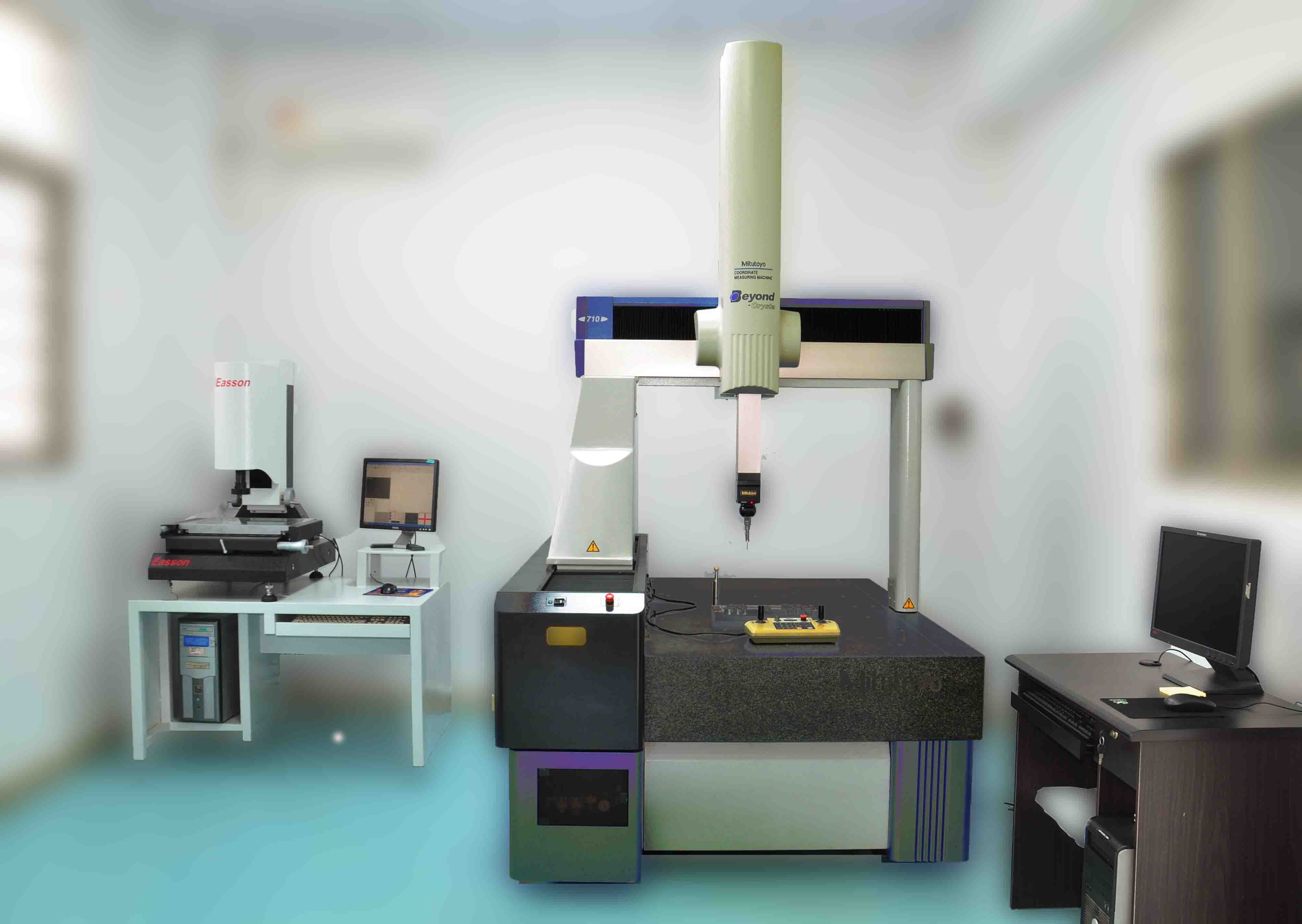

Coordinate Measuring Machine

Coordinate Measuring Machine

Double-head EDM

EDM machine

Grinding Machine

Mirror EDM

Sodick Wire Cutting

Quality Control

We are confident that our QA team will ensure the quality of your project along with the newest equipment, which we are always updating, to cater to the demand of customers.

- Mold Design Control

- Mold Steel Hardness Inspection

- Mold Electrodes Inspection

- Mold Core and Cavity Steel Dimension Inspection

- Mold Pre-Assembly Inspection

- Mold Trial Report and Samples Inspection

- Pre-Shipment Final Inspection

- Export Product Package Inspection

Injection Molding Operations

Topsun is a full service Plastic Injection Molding manufacturer in custom manufacturing. With our experienced tool makers and setters we can achieve optimum product output in a minimum of time. Your product is molded to your specifications and put through our quality inspection department to guarantee accuracy and quality at all times.

- On-site injection plastic mold repair & maintenance

- Injection machines ranging from 50T-1000T

- 24-hour plastic molding manufacturing shifts

- Long and short plastic injection molding production runs

- Insert molding, dual-color molding service

- Extensive capabilities to process engineered raw materials and complex filled-polymer compounds

- Large and small parts

- Low and high volume

- Tight Tolerance and Quality Controls

Logistics / Finalization

Finalization is an end process by our quality team to make sure everything is ready for shipping and meets all the customer requirements and specifications.

Documentation

Complete documentation, 2D Mold Drawing and 3D Mold Drawings, trial parameters, trial video, material certifications, Dimensional Report.

Final Mold Test

Depending on customer requirements we can run the tool for up to 8 hours before shipping (with resin supplied).

Specifications

Quality team will review the original customer specifications to insure all requirements have been met.

Packaging

Vacuum sealed and special shipping container to prevent damage during shipment.